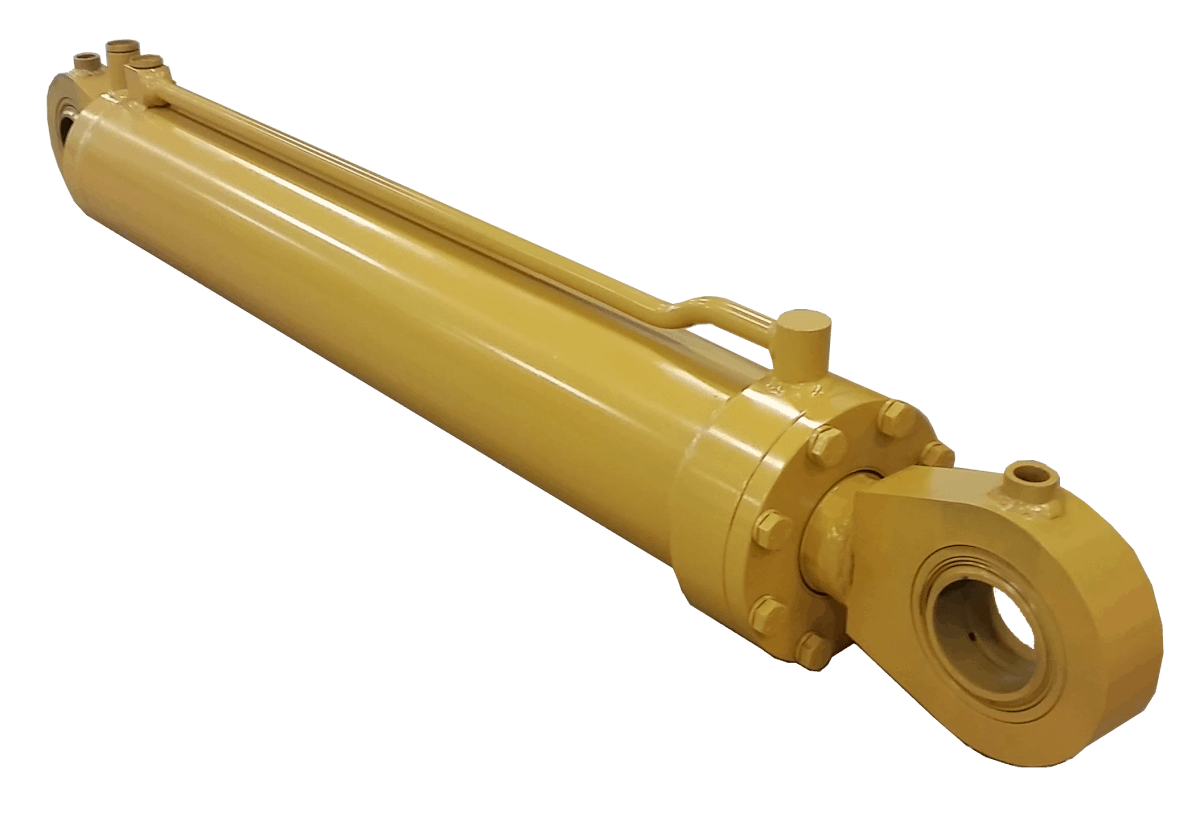

Hydraulic Cylinder Repair

Hydraulic cylinder repair is the backbone of our business. From simple resealing to more complex tube and rod repair or fabrication, no job is too large or too small.

Our cylinder repair service provides an economical way to restore your hydraulic equipment back to operating condition. Our standard cylinder repair includes replacing seals, polishing the rod and honing the tube. We service any brand equipment from industries that include construction, waste handling, recycling, manufacturing, forestry, and agriculture.

Every hydraulic cylinder goes through a stringent inspection process to ensure the highest quality repair in the industry.

When all cylinder repairs are completed, each cylinder is then subject to Hydraulic Pressure Testing. The test is performed by pressurizing the oil in the cylinder’s rod end cavity while blocking the release of oil from the cylinder’s cap end. The test of whether the re-seal has been effective is determined in two ways:

Watch for rod (and piston) drift and external leaks at the rod. If the wrong piston seals have been installed or they have been “cut” during assembly, they will leak and cause the rod to drift.

Watch the rod and cap end gauges readings. If the pressures hold, the reseal has been effective. If the pressures drop and equalize, a leakage path exists either through the seal or past a scratch in the cylinder wall.

A three-position pressure test is done ranging in pressure ratings from 1000psi – 3500psi depending on the cylinder and its application. This simulates the working environment and ensures a leak-free hydraulic.